There are many different designs that are useful for a number of different applications and industries, so it is important to know just how these vibratory screens function and how they might fit into your application. Read More…

Rodix manufactures vibratory feeder controls, inline track drives, drive bases, & bulk storage hoppers for part feeding systems. Our line of vibratory feeder controls feature variable amplitude, variable frequency, line-voltage compensation, UL/cUL Listed, CE Marked, and more. We have experience working with machine integrators, vibratory feed system builders, and manufacturers.

PPM Technologies Holdings, LLC is an innovative industry leader in the vibratory feeder industry. Our main focus has always been to provide our customers with high-quality products with the exact specifications for their needs. With our wide range of products, we are able to serve various industries.

JVI Vibratory Equipment is a leading provider of vibratory process solutions. JVI manufactures vibratory feeders, screens, spiral elevators, conveyors, & grizzlies – all custom designed and manufactured specifically to meet the customer’s exact application requirements. JVI incorporates dry bulk material handling expertise with years of experience to provide innovative, custom machines...

Vibratory bowl feeders are our specialty! For four decades we have been offering products that are guaranteed to last! Our vibratory bowl feeders come with multiple sound abatement options, standard and custom control packages and many other options for your convenience of choice! Visit our website today or get in touch with our customer service representatives by email or telephone today!

More Vibratory Screen Manufacturers

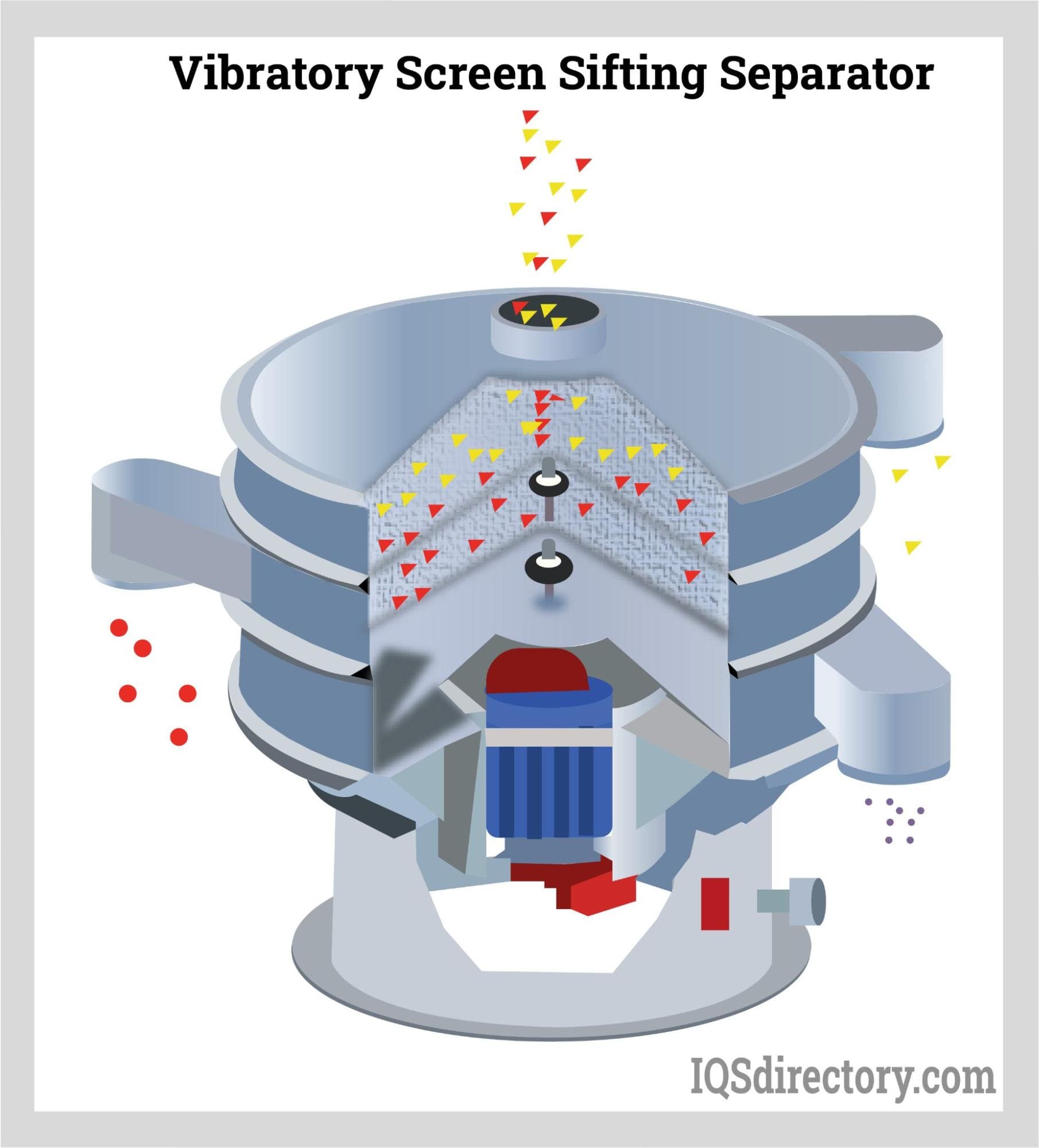

High frequency vibrating screens and normal vibrating screens operate in the same fashion; the high frequency screens only operate at a high frequency in order to filter specific minerals.

Vibratory screens offer many different advantages. They are one of the best ways to filter and separate two or more substances from each other. Vibratory screens do this by breaking down the surface tension between the particles within the substances which allow them to separate more easily.

Vibratory screens often function at an angle in order to further separate materials. This angle provides what is referred to as the popcorn effect. This means that the coarser a particle is, the more likely it is going to be lifted higher while finer particles remain closer to the screen. The rate at which the screen vibrates, or the frequency, can be controlled in order to achieve the desired popcorn effect or separation.

As we stated before there are a number of different applications in which you can find a vibratory screen at work. Some of these applications and industries include, processing powder in coal, metallurgy, wood pelleting, fractionated asphalt pavement, ores and minerals, food, chemical applications and the pharmaceutical industry. Because of this there are multiple designs of vibratory screens available.

It is important to consult with a trusted vibratory screen manufacturer in order to determine what design is best for your application. If you do not have the correct design, or the frequency is not set correctly, you may experience inaccuracies when trying to separate particles as the process is influenced by many different factors, from vibratory equipment capacity to the angle at which the vibratory screen is placed.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services