These are conveyors that employ vibrational energy for imparting static and dynamic forces on aggregate materials to move them up or down a pathway. The surface of the conveyor is typically a smooth trough that contains vibratory components that are attached to cause shaking of this trough lengthwise. Because of this action, bulk products like limestone, coal, gravel, sand, food materials, and others “hop” with the vibration’s frequency towards the trough’s end. Read More…

Rodix manufactures vibratory feeder controls, inline track drives, drive bases, & bulk storage hoppers for part feeding systems. Our line of vibratory feeder controls feature variable amplitude, variable frequency, line-voltage compensation, UL/cUL Listed, CE Marked, and more. We have experience working with machine integrators, vibratory feed system builders, and manufacturers.

PPM Technologies Holdings, LLC is an innovative industry leader in the vibratory feeder industry. Our main focus has always been to provide our customers with high-quality products with the exact specifications for their needs. With our wide range of products, we are able to serve various industries.

JVI Vibratory Equipment is a leading provider of vibratory process solutions. JVI manufactures vibratory feeders, screens, spiral elevators, conveyors, & grizzlies – all custom designed and manufactured specifically to meet the customer’s exact application requirements. JVI incorporates dry bulk material handling expertise with years of experience to provide innovative, custom machines...

Vibratory bowl feeders are our specialty! For four decades we have been offering products that are guaranteed to last! Our vibratory bowl feeders come with multiple sound abatement options, standard and custom control packages and many other options for your convenience of choice! Visit our website today or get in touch with our customer service representatives by email or telephone today!

More Vibratory Conveyor Manufacturers

Vibratory Conveyors: Efficient Material Handling Solutions for Bulk Processing

Vibratory conveyors are specialized mechanical systems engineered for the efficient movement and handling of bulk materials, powders, granules, and irregularly-shaped solids across processing plants and manufacturing facilities. By utilizing a controlled vibratory or oscillatory motion, these conveyors induce a hopping action at many cycles per second, creating a continuous flow of material along the conveyor trough. This unique movement enables the transport of deep beds of material—making vibratory conveyors an ideal choice for applications requiring horizontal or shallow incline conveying. From food processing to mining, vibratory conveyors deliver outstanding versatility and reliability for a wide range of industries.

Are you searching for the best way to move bulk materials with minimal degradation and maximum efficiency? Vibratory conveyors are capable of handling everything from fine powders and chemicals to large, irregularly-shaped aggregates, making them a top solution for demanding environments where gentle handling, hygiene, and adaptability are essential.

How Vibratory Conveyors Work: Principles, Components, and Motion

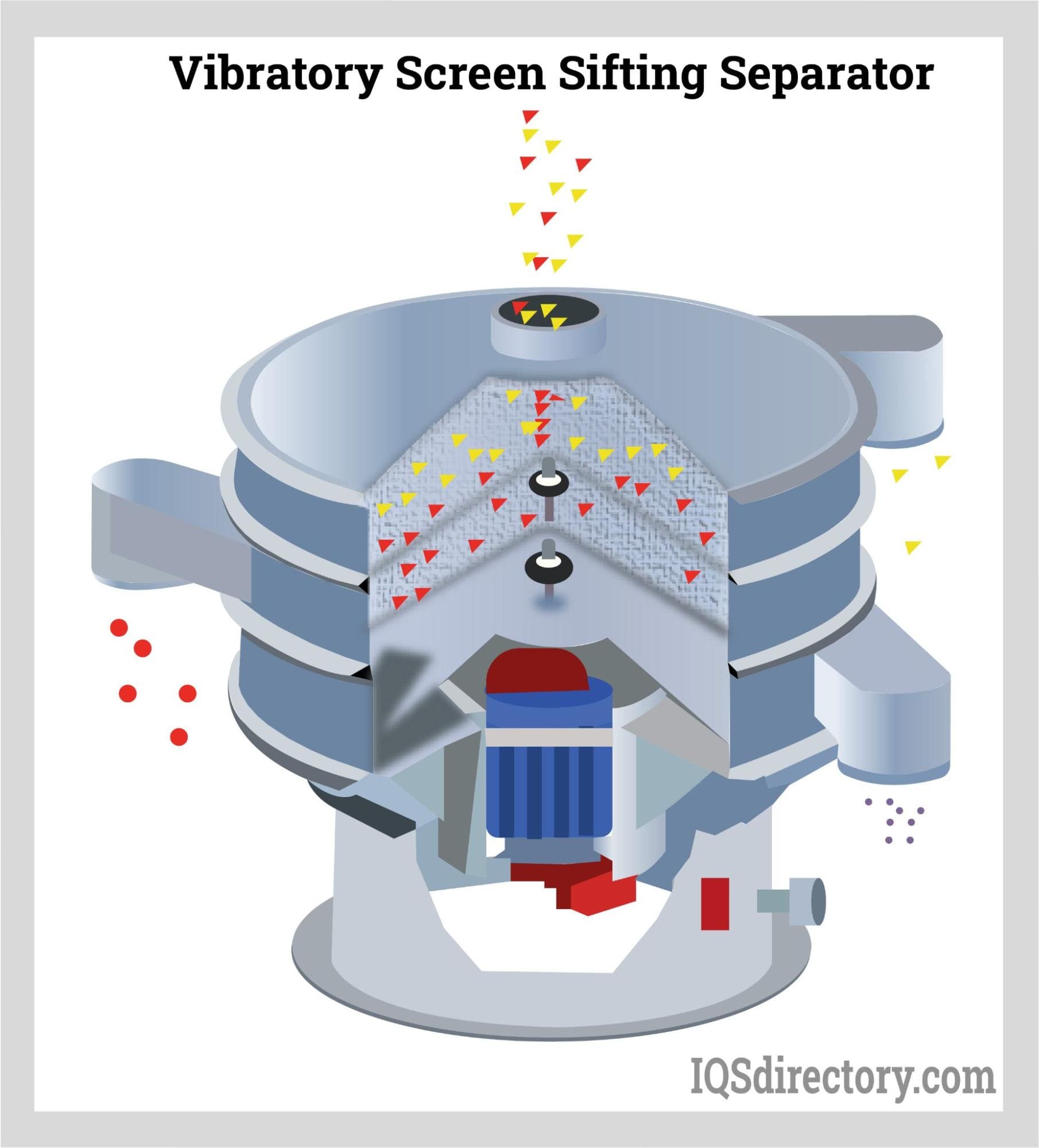

The core function of a vibratory conveyor is determined by its drive mechanism, trough design, and the vibratory motion generated. While the working principles can vary based on the specific type and manufacturer, all vibratory conveyors operate on the principle of imparting rapid, controlled oscillations to the conveying trough. This action is typically achieved through electric motors, electromagnetic drives, or pneumatic systems that transmit a rhythmic motion to the trough, causing the material bed to move forward in a series of small hops.

In the most common vibratory conveyor designs, a motorized drive system applies an oscillatory force to the trough with a defined amplitude and frequency. One full stroke of the trough (trough stroke) equals twice the amplitude of the vibration. Modern vibratory conveyors aim to minimize amplitude while maximizing frequency—delivering rapid, efficient material flow with reduced wear on mechanical components. These are known as controlled vibratory conveyors, as amplitude and frequency can be precisely set and adjusted to match product characteristics and throughput requirements.

Another prevalent design is the natural frequency vibratory conveyor. These units utilize a tuned system of springs, weights, and damping elements, allowing the conveyor trough to vibrate at its inherent natural frequency. This approach reduces energy consumption, increases operating efficiency, and distributes vibratory forces uniformly across the trough for smoother material movement. Natural frequency conveyors are especially valued in high-volume, energy-sensitive applications.

Wondering how a vibratory conveyor differs from other conveyor systems like belt or screw conveyors? Vibratory conveyors are unique in their ability to handle fragile materials with minimal product breakage, reduce dust generation, and simplify cleaning for sanitary environments. Their modular construction and gentle material handling make them a preferred choice for industries with strict contamination control requirements, such as food processing, pharmaceuticals, and specialty chemicals.

Types of Vibratory Conveyors: Choosing the Right System for Your Application

Selecting the optimal vibratory conveyor involves understanding the differences between key conveyor types, each engineered for specific material characteristics, throughput rates, and plant layouts. Below, we explore the most common types of vibratory conveyors and their primary use cases.

Standard-Duty Vibratory Conveyors

Standard-duty vibratory conveyors are designed to handle medium and light-density materials such as wood chips, plastics, lightweight aggregates, and porous rocks. With throughput capacities ranging from 1 to 40 tons per hour and conveying speeds up to 60 feet per minute, these conveyors are ideal for applications demanding reliable, low-maintenance material transport. Modular and portable configurations allow for easy integration into existing process lines or quick repositioning as production needs change.

Where are standard-duty vibratory conveyors most commonly used? These conveyors are widely adopted in food processing, chemical manufacturing, plastics production, recycling, and other industries requiring gentle, consistent movement of bulk solids. Their robust construction ensures long service life and minimal operational downtime, making them a top choice for facilities that prioritize safety and reliability in material handling.

Heavy-Duty Vibratory Conveyors

Heavy-duty vibratory conveyors are purpose-built for the transport of high-density, abrasive, or oversized materials that require greater conveying power and durability. These systems routinely handle metals, minerals, large rocks, foundry sand, and bulk loads exceeding 500 tons per hour at speeds up to 90 feet per minute. Engineered with reinforced troughs, heavy-duty motors, and advanced foundation supports—such as vibration dampers, stands, and dashpots—these conveyors are designed to withstand demanding industrial environments.

What industries benefit from heavy-duty vibratory conveyor systems? Heavy-duty vibratory conveyors are essential in mining, metallurgy, foundry operations, rubber and lumber processing, and large-scale manufacturing plants. Their ability to operate continuously under harsh conditions, combined with customizable power requirements, enables seamless integration into high-volume, high-impact workflows where uptime and productivity are critical.

Oscillating Conveyors

Oscillating conveyors are a specialized subset of vibratory conveyors, distinguished by their low operating frequencies and larger amplitudes of motion. These conveyors are particularly effective for moving bulky, lightweight materials—such as timber, scrap wood, and recyclable components—over short to moderate distances. By using a swinging or reciprocating motion, oscillating conveyors gently transport materials without causing compaction, degradation, or product breakage.

When should you consider oscillating conveyors over traditional vibratory conveyor systems? Oscillating conveyors are ideal for applications where reduced particle degradation and product separation are important, such as moving wood scraps from sawmills or distributing lightweight materials in recycling facilities. Their unique motion profile ensures gentle handling and efficient discharge, even for irregularly-shaped or fragile materials.

Other Vibratory Conveyor Variants

Depending on your specific process requirements, additional vibratory conveyor options may include enclosed sanitary models for food and pharmaceutical applications, inclined vibratory conveyors for elevation changes, and reversible or multi-directional units for flexible plant layouts. Customizations such as adjustable trough widths, integrated screens, and automated feeding controls further enhance performance and adaptability.

Key Applications and Use Cases for Vibratory Conveyors

Vibratory conveyors offer unparalleled flexibility and efficiency in transporting, screening, and processing bulk materials across diverse industries. Some of the primary applications and use cases include:

- Screening and Sizing: Vibratory conveyors equipped with integrated screens efficiently sort materials by size, ensuring uniformity and product quality for downstream processes.

- Fluidizing Bulk Solids: The vibratory motion aerates and fluidizes powders or granular materials, preventing compaction and enhancing flowability for easier handling and processing.

- Cooling and Drying: By spreading materials evenly and maximizing surface exposure, vibratory conveyors facilitate rapid cooling or drying in thermal processing lines.

- Product Leveling and Packing: In automated packaging systems, vibratory conveyors promote even leveling of products in vessels, bins, or hoppers prior to sealing or weighing.

- Elevation and Transfer: Specialized vibratory conveyors can elevate products between processing stages or across plant floors, reducing manual handling and improving workflow automation.

- Moisture Removal: Vibratory conveyors with perforated troughs or integrated drains effectively remove excess moisture from products, streamlining drying and packaging operations.

- Uniform Product Distribution: The controlled motion of vibratory conveyors ensures even distribution of materials across processing equipment, reducing bottlenecks and improving consistency.

- Feeding and Metering: Vibratory conveyors are frequently paired with vibratory feeders to provide precise, adjustable material flow rates for batching, mixing, or continuous processing.

- Waste Handling and Recycling: In recycling plants, vibratory conveyors transport, separate, and distribute waste materials for further sorting and processing, increasing system efficiency.

Do you need to automate bulk material movement in your facility? Vibratory conveyors deliver scalable solutions for industries such as agriculture, mining, food and beverage, pet food, pharmaceuticals, chemicals, plastics, recycling, and more. Their adaptability and efficiency make them a cornerstone of modern bulk material handling systems.

Benefits and Advantages of Vibratory Conveyors

Why should your operation invest in vibratory conveyor technology? Here are the key benefits that make vibratory conveyors a preferred solution for material handling challenges:

- Easy to Clean and Sanitize: Open trough designs and stainless steel construction allow for fast, thorough cleaning, crucial for food processing and pharmaceutical environments where hygiene is paramount.

- Low Maintenance Requirements: With fewer moving parts and robust construction, vibratory conveyors require less maintenance and experience lower wear rates compared to traditional conveyor systems.

- Energy Efficiency: Natural frequency designs minimize energy consumption, lowering operating costs and environmental impact.

- Quiet Operation: Vibratory conveyors operate at reduced noise levels, creating a safer, more comfortable workplace environment.

- Continuous, Reliable Operation: Heavy-duty models are engineered for 24/7 operation, minimizing spillage, leaks, and unexpected downtime.

- Contamination Control: Enclosed or sealed conveyor models protect sensitive materials (like dairy and food powders) from dust ingress and cross-contamination, ensuring product integrity and compliance with industry standards.

- Gentle Material Handling: The controlled vibratory motion reduces product degradation, dust generation, and fines production, preserving product quality and maximizing yield.

- Modular and Customizable: Vibratory conveyors can be tailored to specific plant layouts, capacity requirements, and product characteristics, offering unparalleled flexibility for system designers and engineers.

- Reduced Labor and Automation Integration: Automated vibratory conveyors minimize manual handling, streamline process flows, and integrate easily with upstream and downstream equipment.

- Improved Safety: Fewer pinch points, lower mechanical complexity, and enclosed designs enhance operator safety and reduce the risk of workplace injuries.

How to Choose the Best Vibratory Conveyor for Your Process

Selecting the right vibratory conveyor involves a careful assessment of your application requirements, material characteristics, and operational goals. Consider the following decision factors when evaluating vibratory conveyor companies and product offerings:

- Material Type: Is your product abrasive, fragile, sticky, hot, or prone to segregation? Choose a conveyor design optimized for your material's properties.

- Capacity and Throughput: Define your required tons per hour and peak load capacities to ensure the selected conveyor meets your production targets.

- Sanitary Requirements: For food, pharmaceutical, or chemical applications, prioritize conveyors with easy-to-clean designs, stainless steel finishes, and compliance with industry regulations (such as USDA, FDA, or EHEDG).

- Plant Layout and Space Constraints: Consider conveyor length, width, height, incline, and available floor space to ensure seamless integration into your existing process line.

- Environmental Conditions: Evaluate operating temperatures, humidity, dust levels, and potential exposure to corrosive substances when selecting materials and protective features.

- Drive and Control System: Decide between electromagnetic, motor-driven, or pneumatic actuation based on required adjustability, energy efficiency, and maintenance preferences.

- Customization and Accessories: Explore optional features such as covers, screens, hoppers, gates, and automated controls to maximize performance and ease of use.

- Budget and Total Cost of Ownership: Factor in initial purchase price, expected lifespan, maintenance costs, and energy consumption to determine the best long-term value.

Need expert guidance on selecting the right vibratory conveyor? Consult with leading vibratory conveyor manufacturers and suppliers to discuss your material handling goals, requesting detailed technical specifications, project references, and recommendations for your unique process environment.

Frequently Asked Questions About Vibratory Conveyors

What types of materials can be handled by vibratory conveyors?

Vibratory conveyors are exceptionally versatile, capable of transporting powders, granules, pellets, aggregates, minerals, chemicals, food products, pharmaceutical ingredients, wood chips, scrap metal, and more. Their adaptability makes them suitable for industries ranging from agriculture and mining to food, beverage, and recycling.

How do vibratory conveyors improve process efficiency?

By automating the movement, screening, and feeding of bulk materials, vibratory conveyors reduce manual labor, minimize product loss, enable consistent throughput, and support continuous production. Their low-maintenance, energy-efficient design further enhances operational efficiency and cost savings.

Are vibratory conveyors suitable for sanitary and hygienic applications?

Absolutely. Many vibratory conveyor models are engineered with sanitary features such as stainless steel construction, open-access troughs, and crevice-free designs, facilitating fast cleaning and compliance with FDA, USDA, or EHEDG standards for food and pharmaceutical processing.

How do I maintain a vibratory conveyor system?

Regular maintenance involves inspecting drive components, checking fasteners, lubricating moving parts as needed, and monitoring for signs of wear. Many vibratory conveyors are designed for easy access, minimizing downtime and simplifying routine maintenance.

Choosing the Correct Vibratory Conveyor Company

To ensure the most productive outcome when purchasing a vibratory conveyor system, it's essential to select a supplier with proven expertise, quality manufacturing standards, and responsive customer support. We recommend comparing at least 4 to 5 companies using our vibratory conveyor directory. Each company profile highlights their areas of experience, product capabilities, and includes a contact form for direct communication or quote requests.

How can you streamline your supplier search? Review each vibratory conveyor company website using our proprietary website previewer to quickly assess specialties, certifications, and project references. Use our simple RFQ form to request quotes from multiple vibratory conveyor manufacturers, ensuring you receive competitive pricing and technical guidance tailored to your application.

Investing in the right vibratory conveyor is key to unlocking new levels of efficiency, safety, and product quality in your operation. Explore our directory, connect with trusted manufacturers, and discover how advanced vibratory conveyor technology can transform your bulk material handling processes today.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services