Vibratory bowls were created in the mid 1940’s by Robert Moore. Vibratory bowls work by aligning and feeding small parts and components into a production line for further packaging or processing. The vibratory bowl feeder remains a solid solution for handling and sorting bulk goods for further processing and packaging lines, significantly improving production line efficiency. Read More…

Rodix manufactures vibratory feeder controls, inline track drives, drive bases, & bulk storage hoppers for part feeding systems. Our line of vibratory feeder controls feature variable amplitude, variable frequency, line-voltage compensation, UL/cUL Listed, CE Marked, and more. We have experience working with machine integrators, vibratory feed system builders, and manufacturers.

PPM Technologies Holdings, LLC is an innovative industry leader in the vibratory feeder industry. Our main focus has always been to provide our customers with high-quality products with the exact specifications for their needs. With our wide range of products, we are able to serve various industries.

JVI Vibratory Equipment is a leading provider of vibratory process solutions. JVI manufactures vibratory feeders, screens, spiral elevators, conveyors, & grizzlies – all custom designed and manufactured specifically to meet the customer’s exact application requirements. JVI incorporates dry bulk material handling expertise with years of experience to provide innovative, custom machines...

Vibratory bowl feeders are our specialty! For four decades we have been offering products that are guaranteed to last! Our vibratory bowl feeders come with multiple sound abatement options, standard and custom control packages and many other options for your convenience of choice! Visit our website today or get in touch with our customer service representatives by email or telephone today!

More Vibratory Bowl Manufacturers

The Operating Principle of Vibratory Bowls

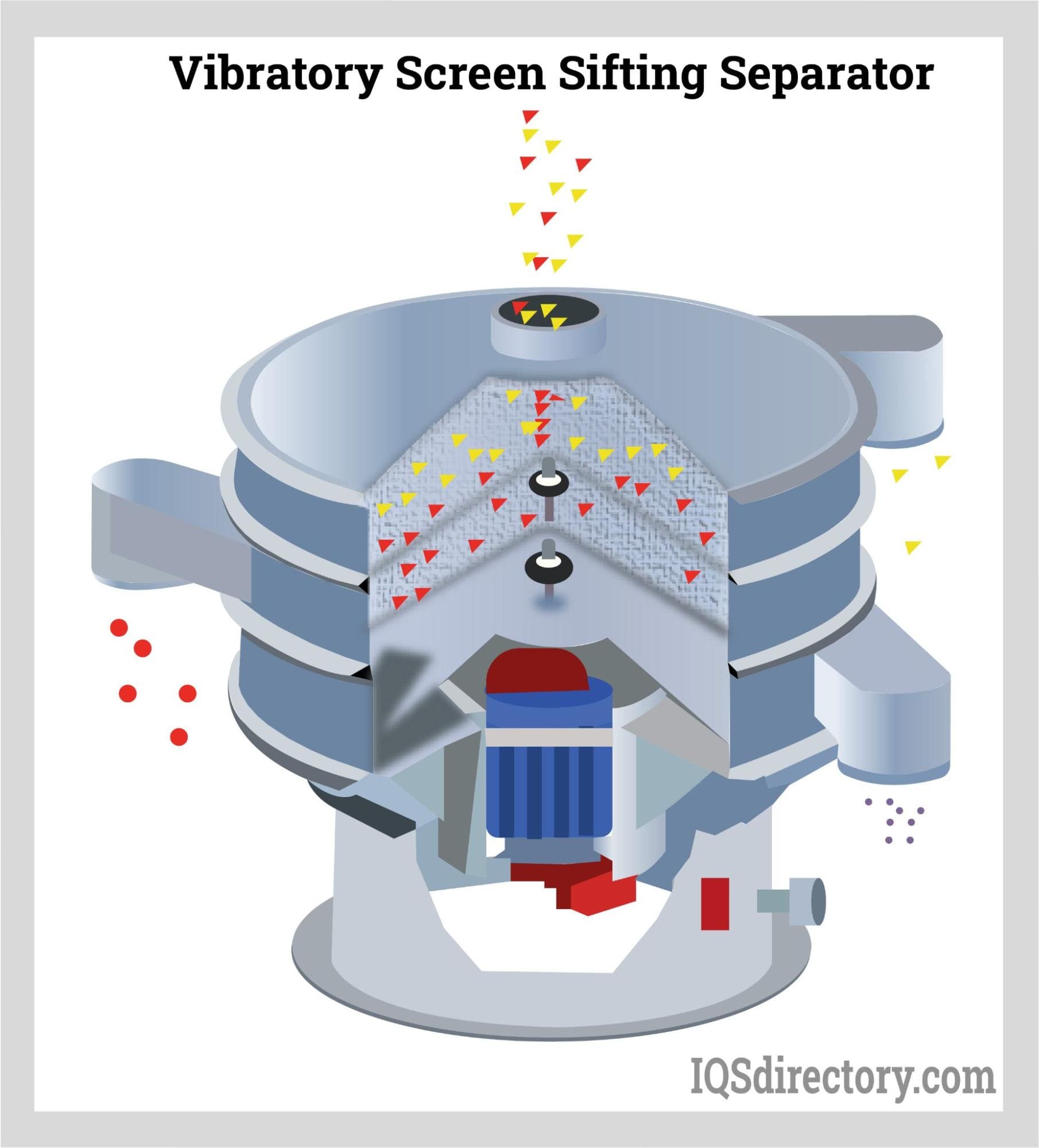

Vibrating feeders are constructed of a vibrating frame, a spring, a vibrator, a vibrating motor device, and a motor. The vibrator is made up of two fixed eccentric shafts with jogged gears. The motor causes the two eccentric shafts to rotate, generating a massive linear power that causes the feeder to vibrate back and forth. As a result, the materials will slip and sling on the funnel as it moves ahead. Smaller materials will fall when the materials pass the screening component, avoiding additional crushing, and achieving the screening goal. Electromagnets are used to generate vibrations.

The device converts electromagnetic waves into mechanical vibrations. The mechanical vibrations are captured and transferred to the bowl's conveying track, which moves the bowl feeder components along the track to feed them into the production line. Under the spring-mounted bowl is a magnetic coil. An external power source magnetizes the coil to provide electromagnetic actuation or vibration.

Because of how the bowl is fastened to the springs, once actuation begins, the bowl is confined to limited vertical movement. Typically, one to six electromagnets are positioned beneath the feeder base. The vibrations in the bowl feeder transport manufacturing once the electromagnetic vibrations are transformed into mechanical vibrations.

Design of a Vibratory Bowl

A vibratory feeder is a self-contained device that manipulates similar pieces into a certain alignment. It is made of a custom-built bowl with ramps and other features tailored to the pieces being fed. An outfeed accumulation track (linear or gravity) to carry parts along and discharge into the assembly machine is usually included and comes in various shapes and sizes. The driving unit vibrates the bowl, causing the pieces to travel up a circular, inclined track. It is available in piezoelectric, electromagnetic, and pneumatic drives.

The bowl feeder is controlled by a vibrating drive unit and a variable-amplitude control box, which may modify the flow of parts to the outfeed track via sensors. The (handmade) tooling is intended to sort and arrange the parts in a consistent, repeatable orientation. The track's length, width, and depth are carefully selected to suit each application, component shape, and size. Special bowl and track coatings are applied to components based on their shape, size, and material. These improve traction, prevent component damage, and reduce acoustic levels.

Vibratory Bowl Types

Vibratory Electromagnetic Bowls

Electromagnetic bowls work by cyclically energizing one or more electromagnets. Electromagnetic drive units have fewer moving parts than electromechanical drives. Instead, the magnetic force impulses supplied by the electromagnet cause the trough to vibrate. As a result, electromagnetic feeders are less expensive for low-volume applications. At rates less than 5 tons per hour, this is true.

Hydraulic or Pneumatic Vibratory Bowls

Pneumatic or hydraulic oscillating pistons power these feeders. The key advantage of employing these sorts is that they are suitable for use in dangerous areas. In addition, the motors that power the pumping units can be found in remote locations. These motors avoid the requirement for costly explosion-proof requirements.

Direct (Positive Mechanical) Vibratory Bowls

Direct or positive mechanical vibratory feeders generate a low frequency and high amplitude vibration using a crank and connecting rod. However, because of the considerable vibration communicated to the supporting structures, positive conveyors are rarely used.

Uses of Vibratory Bowls

Many industries use vibratory feeders, including pharmaceutical, automotive, electronic, cosmetic, food, fast-moving consumer goods (FMCG), packaging, and metalworking. It also services the glass, foundry, steel, construction, recycling, pulp and paper, and plastics industries. Vibratory feeders are a low-cost alternative to manual labor, saving manufacturers time and money.

Considerations When Selecting a Vibratory Bowl

Several aspects must be addressed when choosing a parts feeder, including the industry, application, material qualities, and product volume. The requirement for feeders is sometimes avoided by supplying the components on tape packages or similar, which retain them orientated in the same manner during shipping and storage. These are especially frequent in sectors like electronics, where components must be utilized in a specific orientation that cannot be detected mechanically.

Applications of Vibratory Bowls

Vibrating bowls are useful for handling bulk materials in various industries due to their numerous advantages. For example, the following industries make substantial use of this equipment:

- Packaging \pharmaceutical \food

- Automotive \cosmetic \electronic

- Glass and metal industries

- Steel manufacturing

- Pulp and paper manufacturing

- Plastics manufacturing

- Construction facilities

Aside from the above-mentioned industries, several sophisticated materials also extensively use vibrating feeders. These materials are as follows:

- Materials for recycling

- Solid dry bulk materials

Choosing the Right Vibratory Bowl Supplier

To make sure you have the most beneficial outcome when purchasing vibratory bowls from a vibratory bowl supplier, it is important to compare at least 5 suppliers using our vibratory bowl directory. Each vibratory bowl supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each vibratory bowl business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple vibratory bowl businesses with the same form.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services