A grizzly screen is a sturdy screen with perforated plates used for primary screening material before fragmentation. Grizzly screens, sometimes called rock grizzlies or rock screeners, are static rock separators used to pre-screen bulkier loads. They are set on an incline where huge material, which could damage the screen if allowed to pile on top of it, is slid out of the way.Read More…

Rodix manufactures vibratory feeder controls, inline track drives, drive bases, & bulk storage hoppers for part feeding systems. Our line of vibratory feeder controls feature variable amplitude, variable frequency, line-voltage compensation, UL/cUL Listed, CE Marked, and more. We have experience working with machine integrators, vibratory feed system builders, and manufacturers.

PPM Technologies Holdings, LLC is an innovative industry leader in the vibratory feeder industry. Our main focus has always been to provide our customers with high-quality products with the exact specifications for their needs. With our wide range of products, we are able to serve various industries.

JVI Vibratory Equipment is a leading provider of vibratory process solutions. JVI manufactures vibratory feeders, screens, spiral elevators, conveyors, & grizzlies – all custom designed and manufactured specifically to meet the customer’s exact application requirements. JVI incorporates dry bulk material handling expertise with years of experience to provide innovative, custom machines...

Vibratory bowl feeders are our specialty! For four decades we have been offering products that are guaranteed to last! Our vibratory bowl feeders come with multiple sound abatement options, standard and custom control packages and many other options for your convenience of choice! Visit our website today or get in touch with our customer service representatives by email or telephone today!

More Grizzly Screen Manufacturers

Comprehensive Guide to Grizzly Screens: Types, Applications, Benefits, and Buying Tips

The grizzly screen is a heavy-duty industrial screening solution designed for the rigorous demands of bulk material handling, aggregate screening, and primary scalping in mining, quarrying, and construction industries. While grizzly screens excel at filtering oversized rocks and debris from feed material, they do have a limitation in the maximum size of rocks they can handle. Despite this, their robust construction and high-capacity throughput make them an essential component in mineral processing, ore separation, and material preparation workflows.

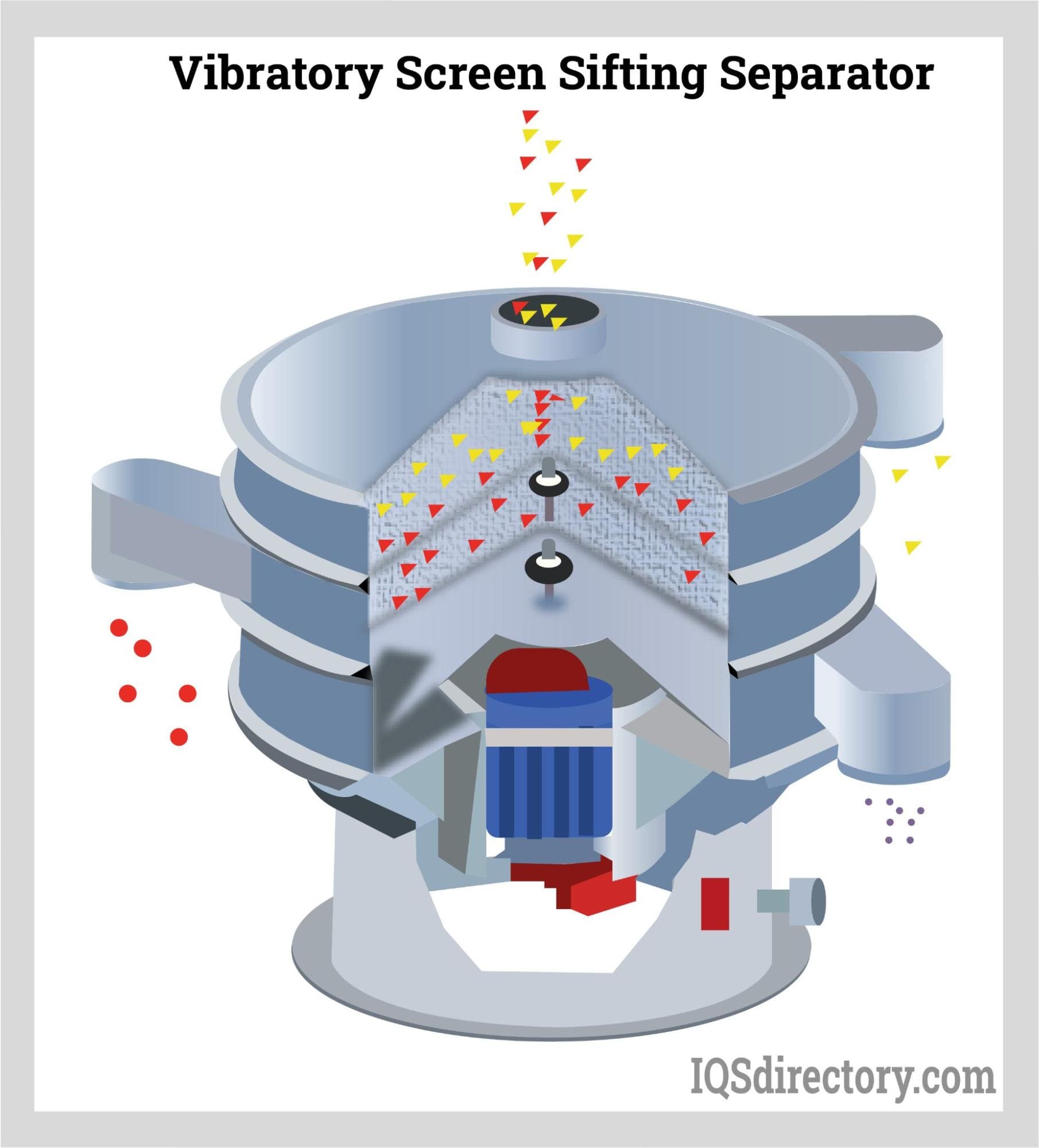

Typically, grizzly screens incorporate grizzly bars fabricated from high-strength, wear-resistant steel or high-manganese casted steel. This ensures exceptional durability even when subjected to abrasive or heavy-impact applications. Grizzly screens are engineered to process both dry and wet materials—including ores, minerals, large stones, gypsum, and foundry materials—making them versatile for various industrial environments. A standard grizzly screen consists of a screening body, connected to a tray and vibrating screen assembly, with a feed box at the base where materials are introduced for processing.

How a Grizzly Screen Functions

The operation of a grizzly screen is based on mechanical vibration and gravity separation. Equipped with robust, diagonally mounted grizzly plates or grizzly bars, these screens efficiently segregate oversized material from finer feed before downstream processing. The design frequently includes two or more grizzly sections, allowing for uninterrupted operation under harsh, high-load conditions.

High-performance vibrators—either electromechanical or electromagnetic—are strategically placed beneath the screening body to generate controlled vibration. This vibratory action propels feed material across the grizzly bars, facilitating effective separation of fines and oversized particles. The entire screen assembly is mounted on a structural framework, usually supported by steel coil springs or leaf springs. These springs serve dual purposes: they act as shock absorbers to minimize the transmission of vibration to the supporting structure and ensure that vibration occurs at the optimal natural frequency for maximum screening efficiency.

Key Components of a Grizzly Screen

- Grizzly Bars or Plates: Heavy-duty, wear-resistant metal elements that screen large rocks and debris.

- Vibratory Motors: Electromechanical or electromagnetic vibrators that induce the screening motion.

- Feed Tray and Box: The entry point for bulk materials, designed for even distribution across the screen.

- Suspension System: Coil or leaf springs that isolate the screen’s vibration and extend operational lifespan.

- Structural Framework: Rigid support structure that houses all components and absorbs operational stresses.

Grizzly Screen Installation

Proper installation is critical for achieving optimal screening efficiency and extending equipment lifespan. During setup, grizzly bars are mounted using spacers, with opening widths tailored to the size distribution of the material being screened. The tray is attached to the main screening body, ensuring that material flows evenly across the screen surface.

The feed box—positioned at the base of the tray—vibrates in sync with the main body, propelled by electromechanical or electromagnetic vibrators placed at calculated intervals beneath the screen. These vibrators create a uniform conveying motion, enhancing throughput and reducing material hang-ups.

The entire assembly is supported by steel coil or leaf springs, which absorb shock and reduce vibration transmission to the supporting structure. For precise, directional vibration, an electric motor is typically installed and calibrated to the structural framework, ensuring consistent material movement and efficient screening performance.

Types of Grizzly Screens

Choosing the right type of grizzly screen is essential for matching your process requirements, throughput expectations, and material characteristics. Below, we review the most common types of grizzly screens, their design features, and optimal use cases.

Linear-Motion Grizzly Screens

Linear-motion grizzly screens are engineered for high-capacity scalping, particularly in mining and aggregate operations. These screens are ideal for removing fine particles from feed material prior to primary crushing, protecting downstream equipment such as jaw crushers and cone crushers from excessive wear.

The vibratory mechanism in linear-motion grizzly screens typically consists of dual counter-rotating shafts with jogged gears. As these shafts rotate, they create a powerful linear force that drives the entire screening assembly. Table feeders can be integrated for applications demanding extremely high capacities and to accommodate bulky, heavy loads commonly encountered in mineral processing and bulk material handling.

Common Applications for Linear-Motion Grizzly Screens

- Primary scalping ahead of crushers in mining and quarrying

- Pre-screening in aggregate production plants

- Removing fines from raw material streams

- Bulk solids handling in industrial processing

Circular Motion Grizzly Screens

Circular motion grizzly screens are designed for high-efficiency pre-screening or post-screening of heavy-duty materials. These screens are widely used in bulk material handling, recycling centers, foundries, and industrial applications where the separation of undersized particles is critical to process flow.

Circular motion is achieved via a sophisticated arrangement of shafts, couplings, and roller bearings. This creates an orbital vibratory motion, which promotes efficient stratification of material across the screen surface. The consistent circular throw is especially effective for managing high-throughput screening tasks in construction waste recycling, industrial minerals, and bulk solids processing.

Common Applications for Circular Motion Grizzly Screens

- Pre-screening in construction and demolition recycling

- Removal of fines in foundry sand and industrial minerals

- Bulk material separation in mining and aggregate plants

- Screening of wet and sticky materials in process industries

Applications of Grizzly Screens

Grizzly screens play a pivotal role across a wide range of industries, offering reliable performance for bulk material screening, particle size separation, and feed preparation. Some of the most common applications include:

- Mining and Quarrying: Scalping run-of-mine ore and aggregate, removing oversized boulders before secondary and tertiary crushing stages.

- Mineral Processing: Pre-screening feed material to enhance downstream grinding and separation efficiency.

- Construction and Demolition: Screening construction debris, concrete rubble, and waste prior to recycling or stockpiling.

- Industrial and Foundry Operations: Handling abrasive or high-volume materials such as foundry sand, gypsum, and minerals.

- Bulk Material Handling: Feeding and sizing materials in warehouses, logistics centers, and port facilities.

- Soil and Compost Screening: Removing rocks, roots, and debris from soil and compost for landscaping and agricultural use.

Interested in How Grizzly Screens Can Improve Your Operation?

What are the best grizzly screens for my industry?

How do I size and select a grizzly screen for my material?

Which grizzly screen is best for wet material handling?

What are the maintenance requirements for grizzly screens?

Benefits of Grizzly Screens

Investing in a grizzly screen delivers significant operational and economic advantages for businesses engaged in material processing, aggregate production, and heavy industrial screening. The key benefits include:

- High Screening Efficiency: Grizzly screens efficiently separate oversized and undersized material, improving throughput and reducing bottlenecks in downstream equipment.

- Versatility: Available in a wide range of sizes and configurations to accommodate various feed materials, capacities, and installation footprints.

- Rugged Construction: Manufactured from abrasion-resistant metals, grizzly screens are built for longevity in demanding environments, withstanding impact from large rocks, ores, and debris.

- Low Maintenance: Minimal moving parts and self-cleaning action reduce the need for frequent maintenance, resulting in lower total cost of ownership compared to alternative screening equipment like topsoil screeners or trommel screens.

- Cost-Effective Operation: Lower operating and maintenance costs make grizzly screens a smart investment for facilities seeking to optimize their screening processes.

- Self-Cleaning Action: Vibratory movement prevents material buildup, speeding up production and minimizing downtime due to screen blinding or plugging.

- Impact Protection: The robust grizzly bars absorb shocks and protect screens and downstream equipment from damage caused by large or heavy feed material.

- Scalability: Multiple deck configurations and modular construction enable easy adaptation to changing production requirements.

- Enhanced Safety: By removing hazardous oversized objects early in the process, grizzly screens contribute to a safer workplace and reduce equipment damage risk.

Decision Factors: How to Select the Right Grizzly Screen

Choosing the optimal grizzly screen for your application depends on several critical factors. Evaluating these elements will help you align your purchase with your operational goals and maximize your return on investment:

- Material Characteristics: Consider hardness, moisture content, shape, and abrasiveness. Wet, sticky, or highly abrasive materials require specialized screen designs and materials.

- Feed Rate and Capacity: Choose a grizzly screen sized for your peak throughput requirements to avoid overloading and maximize efficiency.

- Particle Size Distribution: Select grizzly bar spacing and deck configuration based on the size range of material you need to separate.

- Installation Environment: Factor in available space, mounting options, and accessibility for maintenance.

- Power and Vibration Requirements: Determine the type of vibrator (electromechanical vs. electromagnetic) and motor power necessary to deliver optimal screening action for your feed material.

- Budget and Lifecycle Costs: Assess initial investment, operating costs, and expected lifespan to ensure cost-effectiveness over time.

- Customization Needs: Consider whether you require special coatings, custom bar profiles, or integration with feeders and conveyors.

Want to Compare Grizzly Screen Suppliers?

Where can I find the top grizzly screen manufacturers?

How can I request quotes from multiple grizzly screen suppliers?

What certifications should a grizzly screen supplier have?

Grizzly Screen Maintenance and Longevity

Regular inspection and maintenance are essential to ensure the long-term reliability of your grizzly screen. Key maintenance tasks include checking for wear on grizzly bars, ensuring vibratory motors are securely mounted and lubricated, and inspecting coil or leaf springs for fatigue or damage. Many modern grizzly screens are designed with quick-access panels and modular components to simplify routine service and minimize downtime.

- Daily Inspection: Check for material build-up, bar wear, and secure fasteners.

- Weekly Maintenance: Lubricate bearings and inspect vibratory motors.

- Periodic Overhaul: Replace worn grizzly bars, springs, and other critical components as needed.

Choosing the Proper Grizzly Screen Supplier

To ensure the best outcome when purchasing a grizzly screen, it is vital to select a reputable, experienced supplier who can provide tailored solutions for your specific needs. We recommend comparing at least four suppliers. Each grizzly screen supplier has a detailed business profile outlining their experience, manufacturing capabilities, and product specialties. Reach out directly using dedicated contact forms to request more information or obtain a custom quote.

Leverage our proprietary website previewer to quickly assess each supplier’s expertise, and use our streamlined RFQ (Request For Quote) form to efficiently contact multiple businesses simultaneously. This approach saves time and ensures you receive competitive, comprehensive proposals tailored to your project requirements.

Ready to take the next step? Request a quote from multiple grizzly screen suppliers now or compare manufacturer certifications and industry experience to make a confident, informed purchasing decision.

Frequently Asked Questions About Grizzly Screens

- What is the maximum rock size a grizzly screen can handle? This varies depending on the screen model, bar spacing, and structural design. Consult the manufacturer’s guidelines for specific capacity ratings.

- How do I determine the optimal bar spacing for my material? Consider the particle size distribution of your feed and the desired separation cut-point. Many suppliers offer engineering support for custom bar spacing.

- Can grizzly screens be used for wet or sticky materials? Yes. Many grizzly screens are designed to handle wet, sticky feed, but using the proper bar configuration and anti-blinding features is recommended.

- What industries use grizzly screens? Grizzly screens are used in mining, aggregate production, mineral processing, construction, foundries, recycling, and more.

- Are grizzly screens easy to maintain? Yes. Their rugged, simple construction and self-cleaning action minimize maintenance needs compared to other screening solutions.

Conclusion: Unlocking Productivity with Grizzly Screens

Grizzly screens are an indispensable asset for any operation requiring robust, high-throughput screening of bulk materials. Their unmatched durability, efficiency, and versatility make them the preferred choice for mining, aggregate, construction, and industrial material processing. By understanding the types of grizzly screens, their core benefits, and critical selection criteria, you can optimize your production workflow and reduce downtime, ensuring a high return on investment.

Explore our full directory of grizzly screen suppliers to find the perfect solution for your application, or contact us for expert guidance on sizing, selection, and integration with your existing equipment.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services